Ethan Huang

2nd Year Electrical Engineering Student

at Carleton University

2nd Year Electrical Engineering Student

at Carleton University

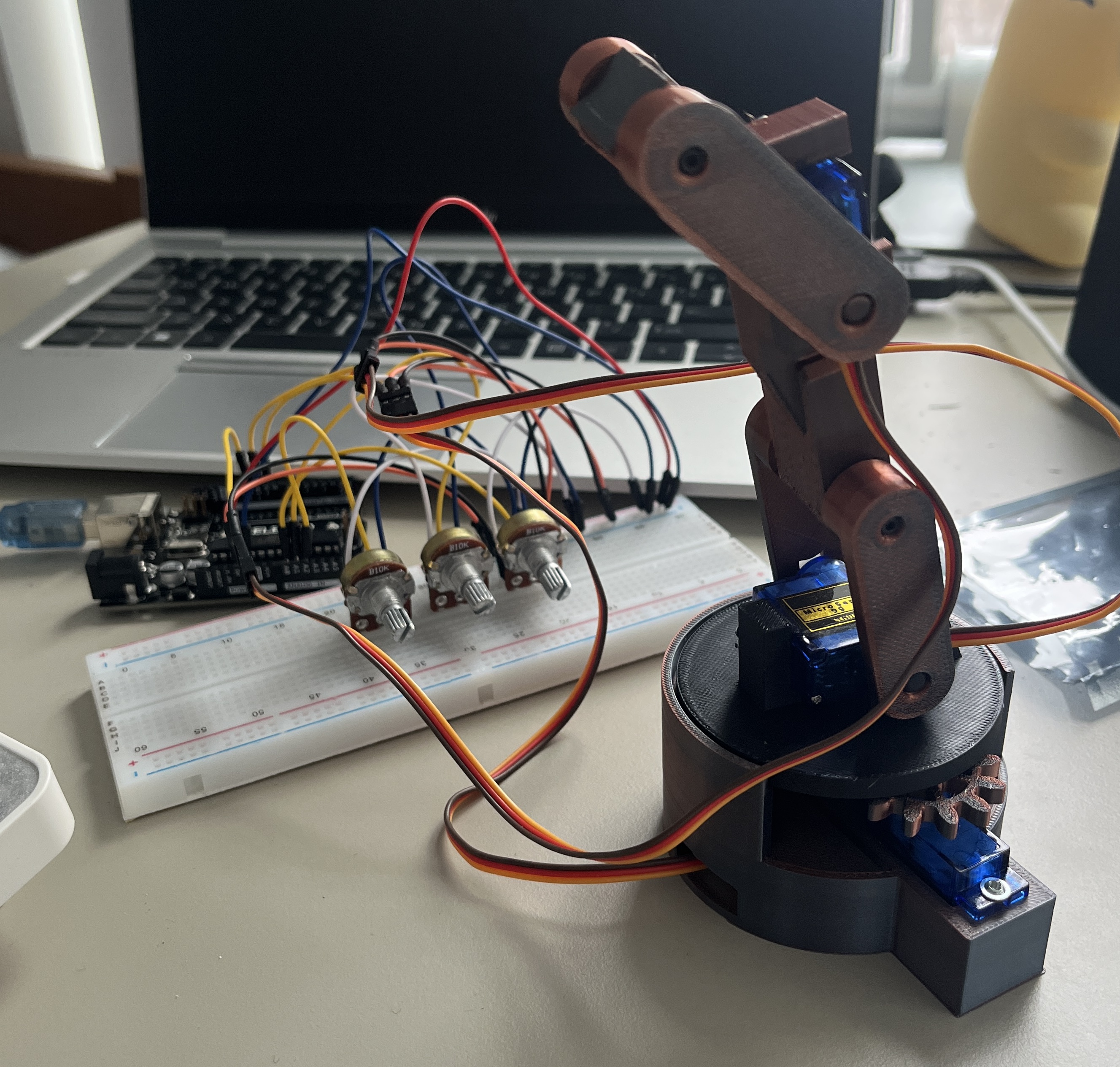

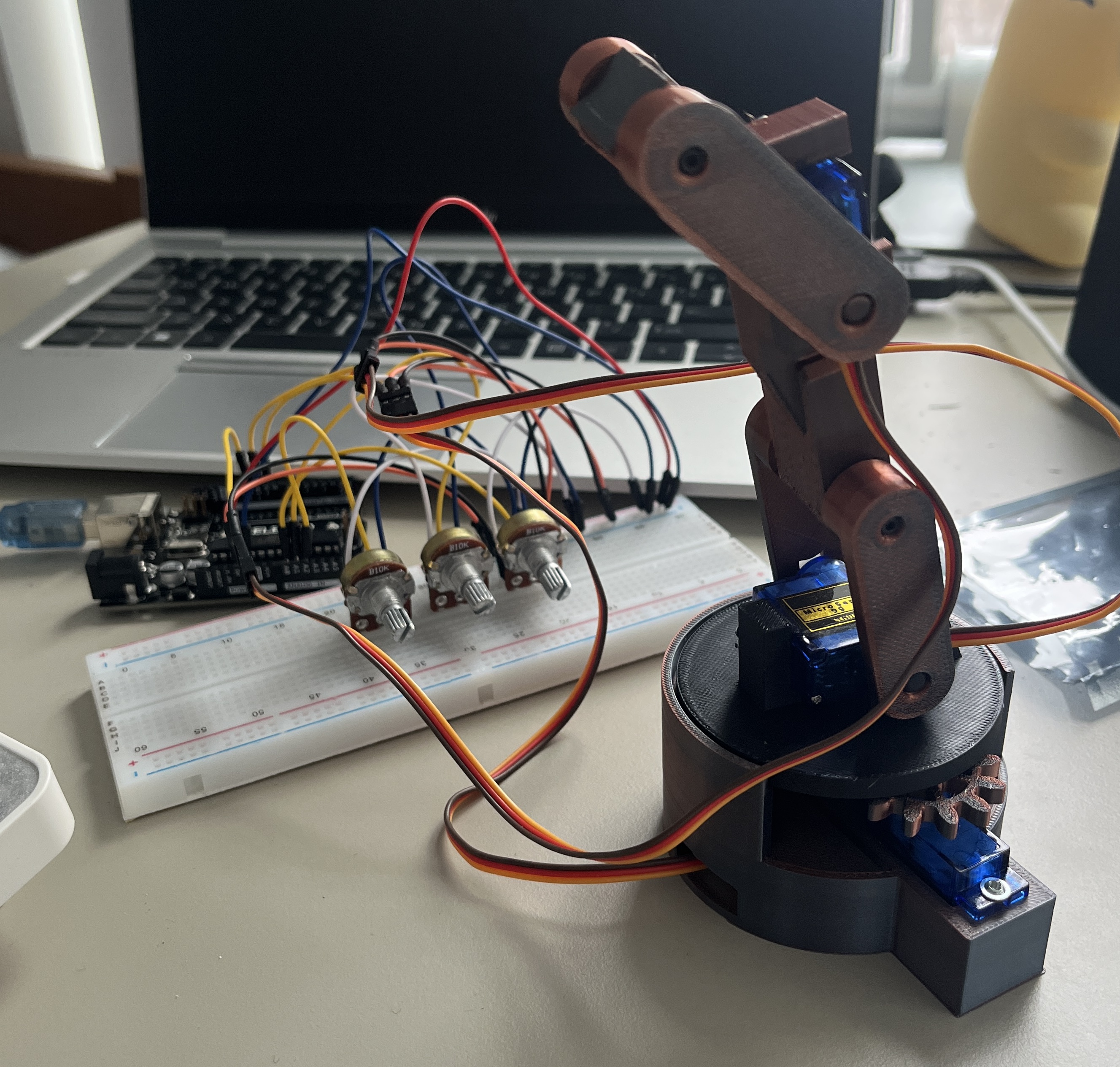

Developed an Arduino-controlled robotic arm, prototyping and testing the circuit on a breadboard

Programmed servo motor control in C++ using the Arduino IDE to enable precise arm movement

Used a potentiometer as an analog input for real-time control of the arm's position

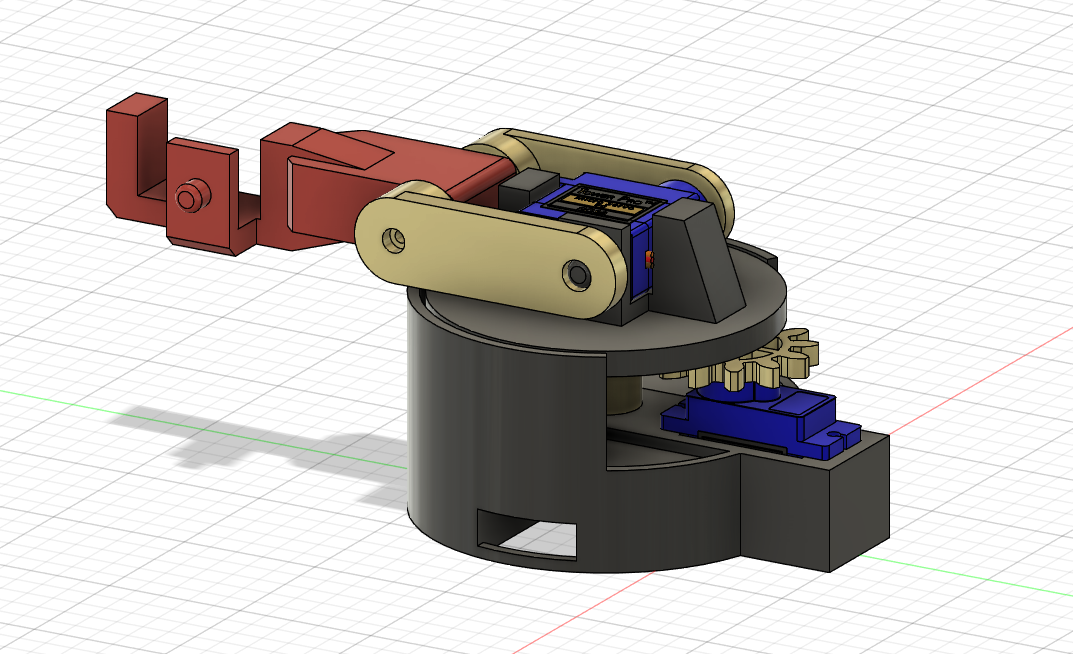

Designed the robot arm chassis and gears using 3D CAD software

Video demonstration of Robotic Arm being controlled by potentiometers.

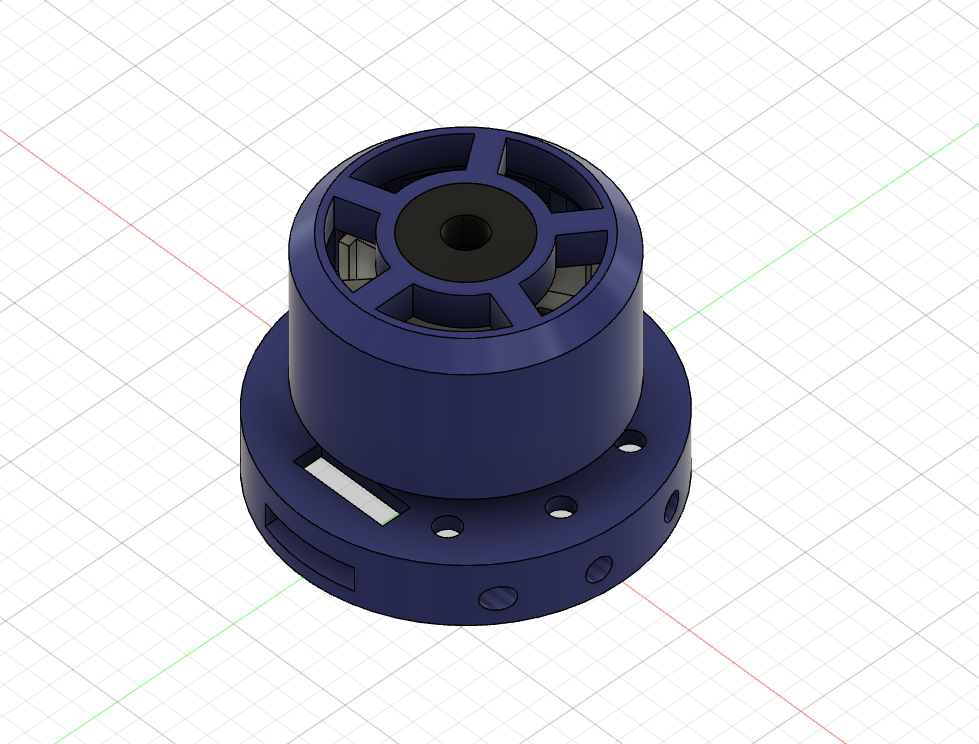

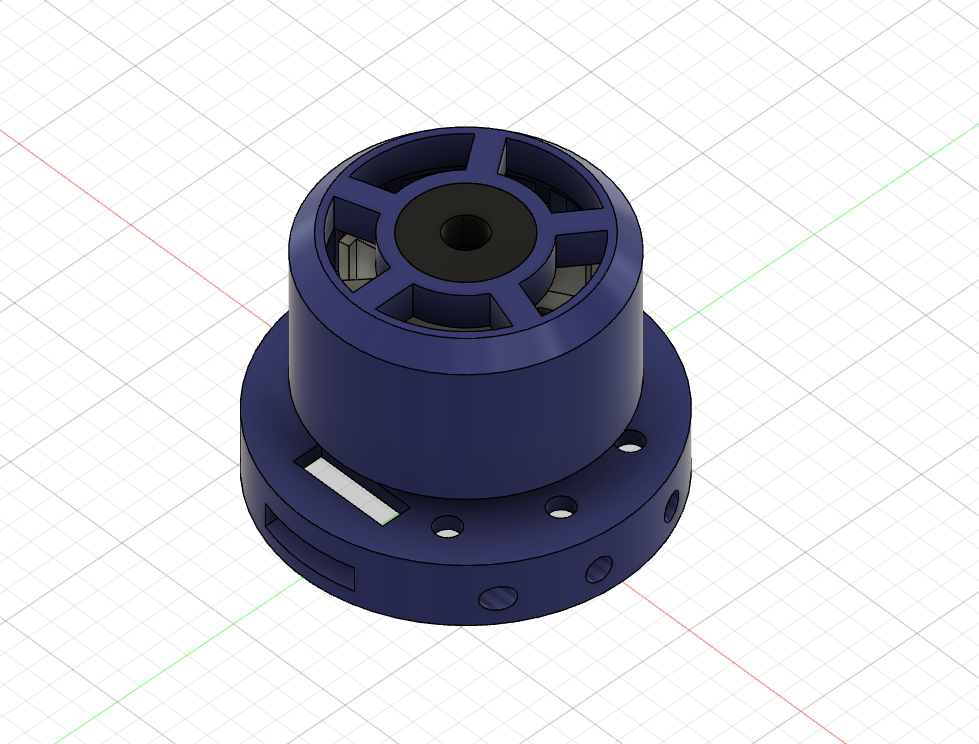

3D CAD Model of Robotic Arm made in Fusion 360

The RED component is a segment which houses a servo motor, and theoretically allows for infinite stages to allow for range of motion.

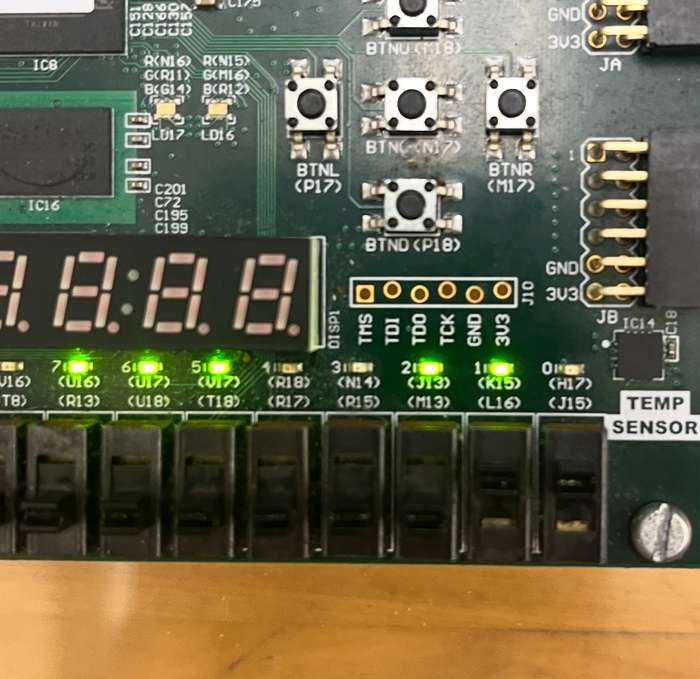

Designed a digital vehicle brake and turn-signal control system using Verilog HDL, defining the system’s logic and state behavior

Implemented both combinational and sequential logic, including D flip-flops and clock division, to manage signal timing and control flow

Verified correct operation through comprehensive testbench simulations in Xilinx Vivado

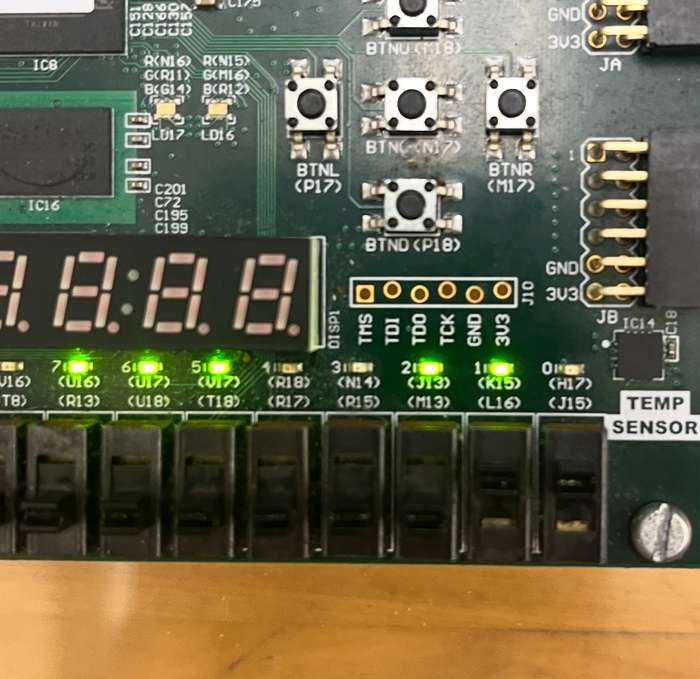

Synthesized the design and deployed it onto a Nexys A7 FPGA board for hardware-level validation

Video demonstration of the Brake Lights Verilog circuit after being synthesized onto the FPGA Board for visual representation.

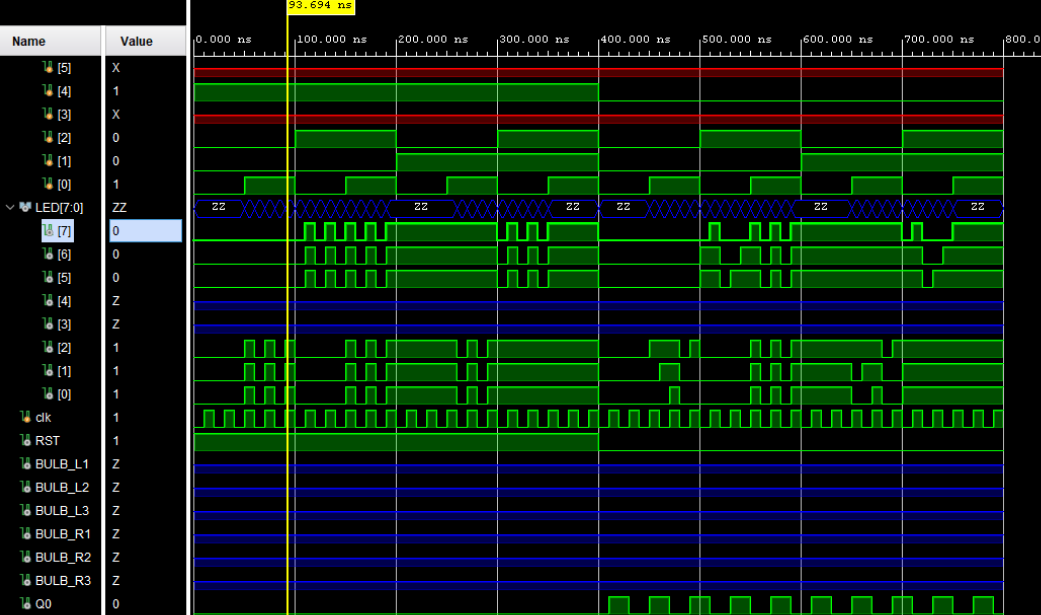

Brake Light Module Testbench Time Diagram

Testbench module output written in Verilog to simulate the behaviours of logic circuit before synthesizing onto FPGA Board.

Designed and built a custom brushless DC motor, integrating mechanical and electrical components into a functional system

Modeled the motor housing and structural components in Fusion 360 and fabricated them using a Bambu Lab P1 3D printer

Integrated permanent magnets, a LiPo battery, ESC, and servo tester to drive and control the motor

Soldered and assembled all electrical connections, applying electromagnetic and DC motor theory to achieve reliable operation

Video demonstration of DC Motor spinning, controlled by servo tester.

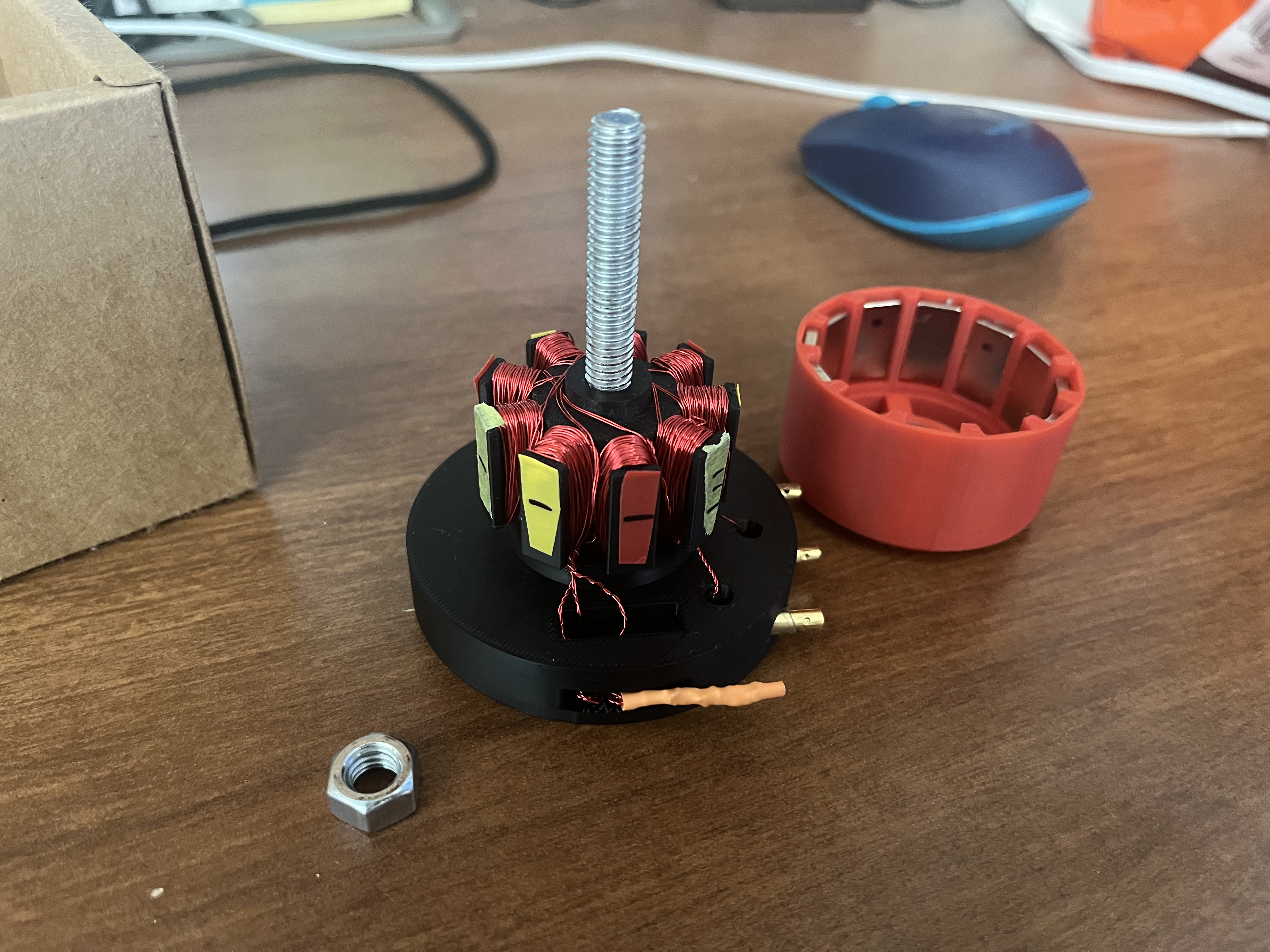

DC Motor Assembly presenting the motor's stator(on the left) and the rotor(on the right).

The stator is made from 3 seperate copper wires which are winded around the red, yellow, and green components respectively.

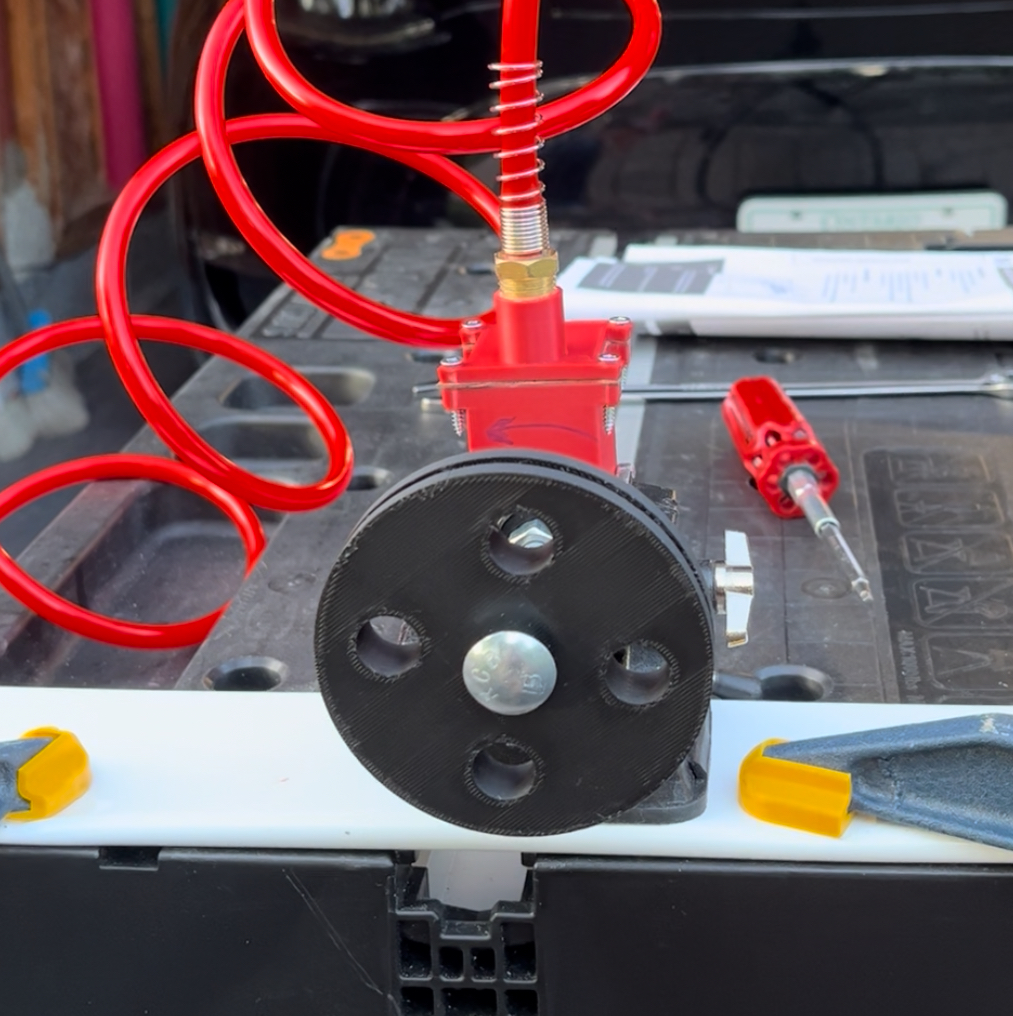

Designed and built a compressed air engine from scratch, demonstrating the mechanical operation of pistons and engine systems

Modeled all engine components in Fusion 360 and fabricated them using a Bambu Lab P1 3D printer

Applied 3D printing dimension and tolerance constraints to ensure proper fit, motion, and air sealing between components

Assembled and tested the engine using a compressed air supply, safely operating an air compressor to validate functionality

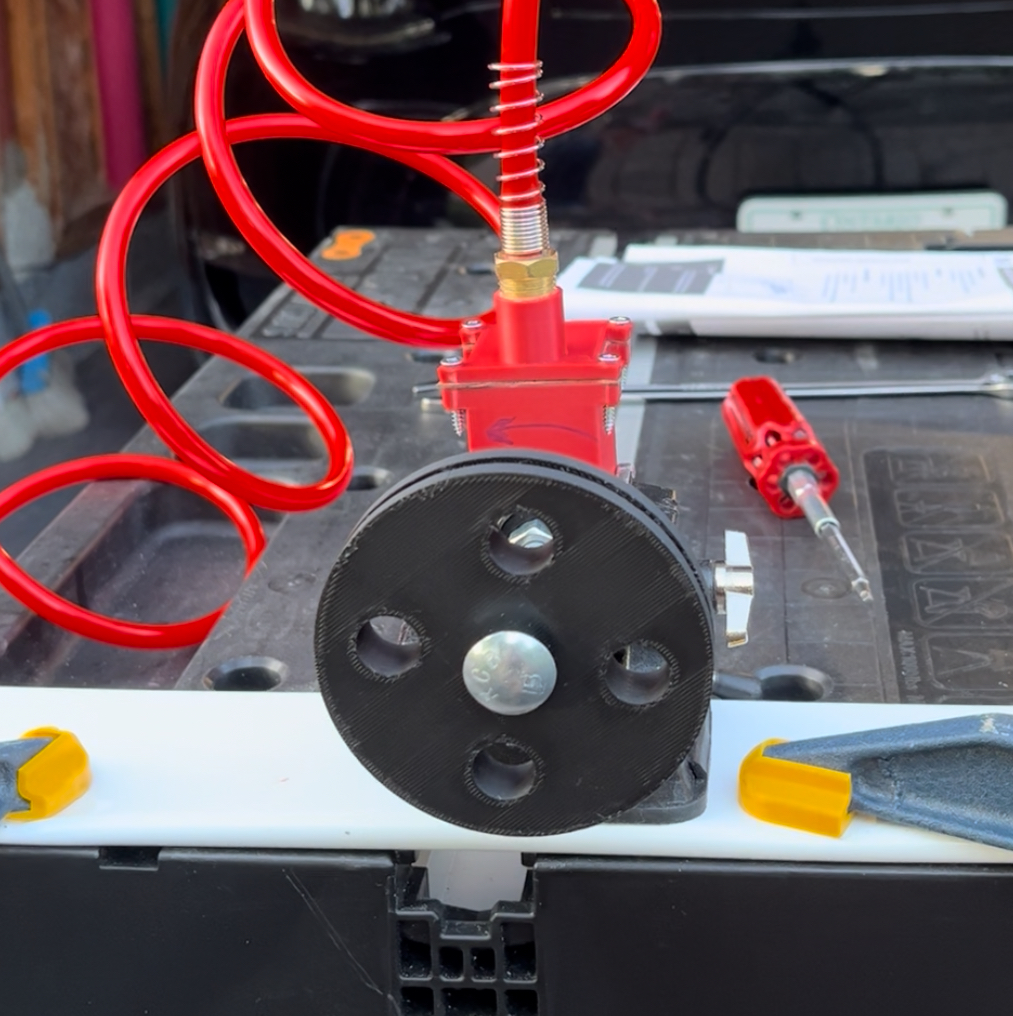

Video demonstration of the Compressed Air Engine rotor spinning.

!!! AUDIO WARNING !!!

Nuts and Bolts attached to rotor are to provide extra mass for increased momentum.

3D CAD Model of Air Engine made in Fusion 360

The RED component represents a ball bearing, and the YELLOW component represents a bolt used as an axle. The rest of the components were 3D printed.

Get in Touch